How does the frost appear ?

Frost appears when two factors are reunited: the presence of liquid water in the form of droplets and temperatures below zero. Supercooled water droplets can be found in clouds and fog met by planes in flight. When meeting the cold surface (temperature below zero) of the plane, these droplets freeze and frost appears. Therefore, frost is not due to precipitation. The apparent wind caused by the plane speed emphasizes frost development. Higher risks of frost occur between 0°C and -15°C. It then becomes a hard or friable ice layer, more or less opaque, which adheres to the plane surface. The more the plane parts are exposed to the wind, the more likely they are to be affected by ice and frost issues. It is especially the case for leading edges, propellers and antennas.

In what ways can frost be an issue for aviation ?

Frost appearance on a plane can cause some in-flight security issues. Here are some scenarios caused by frost:

- Flight control surfaces (ailerons, flaps…) and steering mechanisms can be paralyzed by ice and frost.

- Frost can make the plane heavy and change the mass distribution and the aerodynamic characteristics. The lift can be reduced and it could lead the aircraft to stall.

- Some bits of frost can come off the plane surface and be aspirated by the engines and damage them, or hit a propeller and break it.

- Frost can wreck wired antennas and distort the signal or lose it completely.

What are the current solutions against frost and ice in aeronautics ?

Currently, some solutions against ice and frost exist, both on the ground and in flight, but there are also some anti-icing methods to avoid frost appearance. These systems aim at preventing the ice appearance before its thickness becomes dangerous.

De-icing methods on the ground: get rid of the frost once the plane has landed

On the ground, planes are de-iced thanks to the high-pressure spraying of a mix of hot water and glycol (propylene glycol or ethylene glycol). This operation, which usually takes between 5 and 10 minutes but can also take 30 minutes if there is a lot of ice on the plane, combine a mechanical action, a thermal action and a chemical action. Mechanical thanks to the spurt pressure which pierces the ice and sweeps it away. Thermal thanks to the ice melting which helps to take the ice off the surface. Chemical, because the glycol protects the surface from the frost appearance.

Anti-icing methods: avoid the frost appearance

To avoid the inconvenience of frost, it is possible to use anti-icing methods. The idea is no longer to get rid of the frost but to prevent its appearance.

After the de-icing, it is possible to protect the plane from frost thanks to the spraying of an anti-icing fluid. This fluid is the same as the one used for the deicing except that this time, the fluid is not diluted and is sprayed with a lighter spurt to form a 2 to 3mm layer on the surfaces to protect.

Deicing methods in flight: get rid of the frost when the plane is flying

Once in flight, different deicing methods are possible and some of them can be combined.

It is possible to deice some parts of the plane with some electrothermal systems (ETIPS). The goal is to keep the external temperature of the shielding above 0°C. Some heating elements are incorporated in the leading edges, under the wings shielding and other surfaces of the aircraft to deice them.

For planes with turbojets, there is a deicing method using the warm air from the turbine. The aim is, as for the electrothermal systems, to keep the external temperature of the shielding above 0°C. By spreading the warm air along the inside of the wings and ailerons, this system avoids frost formation by guaranteeing that the external surface is always above 0°C.

Deicing can also be mechanical thanks to pneumatic systems inflated on leading edges and airfoils to break the ice. Connected to a pneumatic actuation system and controlled by a sensors system, a boot on the leading edges is inflated with compressed air during icing conditions. The ice layer is then expelled thanks to the mechanical shock provoked by the boot inflation.

The TKS (Tecalemit-Kilfrost Sheepbridge Stokes) system, a chemical system, can also be used. It diffuses a deicing fluid through micropores on the leading edges and the empennage to avoid ice formation and adhesion.

What are the issues caused by the current deicing solutions ?

Generally, current deicing solutions cause 4 problems: their energy consumption, up to 40% of the total power produced by a plane according to Romain Rioboo, Design Engineer at Euro Heat Pipes, their cost, the workforce they need and their environmental impact.

To be more precise, let’s take each solution one by one to understand its drawbacks:

- Glycol fluid spraying: Even if it is nontoxic for humans, the glycol remains a chemical substance which can be easily spread in ecosystems (soils and waterways) if no measure is taken during the spraying. Propylene glycol should be used through a containment system to hold the fluid back and avoid its discharge into the environment.

- Electrothermal system (ETIPS): To function, this system should cover the whole wings surface which represents an important extra weight. This extra weight leads to extra energy consumption. In addition to that, the electrothermal deicing system needs an important and dedicated power supply, which, once again, increases the energy consumption of the plane.

- Bleed air heat: Above the fact that this solution can only be used by planes with turbojets, this solution consumes a lot of energy.

- Pneumatic de-ice boots: By its functioning, the pneumatic system is not adapted to other plane surfaces than the wings. This system is light and does not consume a lot of energy but it can change the aerodynamic characteristics of the plane. Moreover, the system wear requires regular maintenance and frequent replacement.

- TKS system: The problem with the TKS system is the finite capacity of the tank. TKS fluid tanks usually have a capacity for 1 or 2 hours in normal conditions. Also, the TKS system is designed as an anti-icing system, which means that it should be used quickly in icing conditions, even before the frost appearance. If the pilot waits too long to inject the fluid made with ethylene glycol, or if frost is appearing too fast, the pores would be obstructed which would avoid the seepage.

To solve these issues, some companies and researchers develop new deicing solutions.

What are the new solutions and the new actors in aircraft deicing ?

We have just explained that the current deicing solutions consume are energy-consuming, expensive and/or dangerous for the environment. Some studies and research are made to develop new deicing solutions, lighter, energy-efficient and more sustainable.

Research of new hydrophobic materials and coatings

The solution could be in the materials used in aircraft manufacturing.

Some American researchers are working on hydrophobic materials which avoid frost formation by preventing the droplets from spreading on the surface. A team of researchers from the Harvard School of Engineering and Applied Sciences took its inspiration from biomimetics to develop an ice-free nanostructured material. The material in question can avoid frost formation at really low temperatures (down to -30°C). Click here to get more information about this research.

Also, between October 2018 and December 2021, the research centre Tecnalia was working on a passive solution to prevent ice deposits on plane surfaces. This project focused its attention on the air cycle machine (ACM) but the solution could also be interesting for other parts of the plane, the wings for example. Currently, the deicing of ACM pipes consists of applying high temperatures onto these pipe surfaces. The ERICE project develops new deicing technics to prevent the ice from getting fixed to the plane surface. The team has developed new hydrophobic treatments for different types of substrates. The tests made on a test rig showed real potential. Click here to learn more about the ERICE project.

Passive deicing system

Within the scope of the CleanSky2 programme, the Belgian company Euro Heat Pipes has developed a deicing system using motor heat. The PIPS (Passive Ice Protection System) project, started in 2016 and finished in December 2020, aimed at designing a passive system able to carry the motors residual heat to the air intakes to avoid frost formation on the edges. The PIPS project has achieved technology readiness level 5, the concept has been demonstrated but the technology has to be improved. Click here to have more information about the PIPS project.

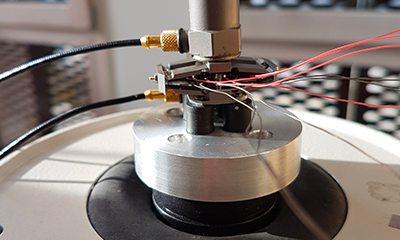

Piezoelectric deicing systems

For decades, some studies and research have been made on deicing systems using piezoelectric actuators. These electromechanical systems use a mechanical force to break the ice and make it fall from the plane’s surface. Piezoelectric actuators placed on the surface to deice make a distortion which to remove the ice. PYTHEAS Technology is working on this deicing method for few months and first results are promising. This piezoelectric deicing system is effective, low-consumption and can participate in the decarbonization of regional aircraft.

Deicing for aeronautics is a R&D subject both for researchers and manufacturers, and PYTHEAS Technology fervently works on it.

What does PYTHEAS Technology offer for aircraft deicing ?

Within the scope of the PARIDES research project, “Project of an Incremental Regional Aircraft more DEcarbonated et more Sober”, PYTHEAS Technology got into the development of a deicing and ice detection system. PYTHEAS Technology offers a deicing solution for regional aircraft. For example, we work with ATR on its ambition to reduce the environmental impact of regional air transport. Our piezoelectric deicing system is effective, compact and low-consumption (reduces by 10 the deicing system consumption of a plane).

If you are interested in this project, do not hesitate to contact Simon Clément to talk about it.