Non-Destructive Testing to evaluate the structures, systems and materials’ health without causing damage

A lot of sectors and activities need more or less frequent controls of equipment and systems, especially to ensure the users’ safety. For example, road structures such as bridges, motoring, aerospace or oil & gas are some sectors in which a failure could have disastrous consequences.

To control their integrity, these systems and structures usually go through some destructive, semi-destructive or non-destructive tests. The goal of Non-Destructive Testing (NDT), or Non-Destructive Evaluation (NDE), is to check the integrity of a specific structure or part without causing damage. Unlike destructive or semi-destructive testing, NDT does not alter the tested component, which, therefore, can be reused normally. This is a way to save both time and money in the products, materials and structures evaluation process.

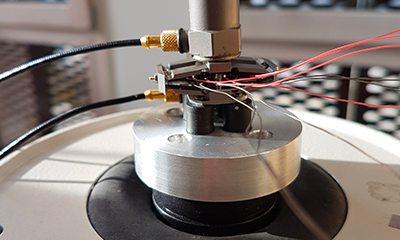

NDT includes different methods and techniques such as eddy-current testing, holography, magnetic particle inspection, tracer-gas leak testing or ultrasonic testing. There are tens of methods for both surface and volume control.

Non-destructive testing can be carried out during production, to detect manufacturing defects, or in use, to detect fatigue, wear & tear damages.