4.0 industry has an increasing need for smart sensors that can be integrated to an industrial IoT network to improve measures. PYTHEAS Technology’s sensors are non-invasive and adapted to all kinds of fluid (from hydrogen to painting).

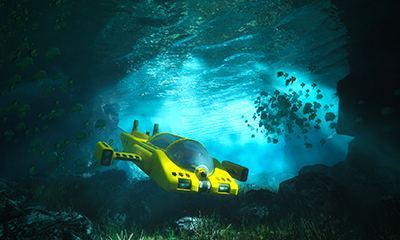

Two families of ultrasound flowmeters exist and are developed by PYTHEAS Technology: by Doppler effect or by time-of-flight. In addition to providing high accuracy and low time response, these flowmeters are non-intrusive, since only acoustic waves need to penetrate the fluid.

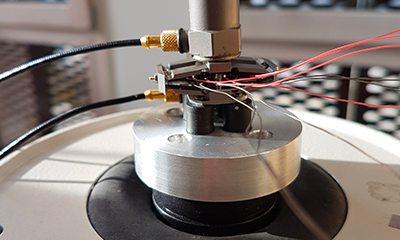

Doppler flowmeters have two piezoelectric transducers, one emitter and one receiver, positioned next to each other. The particles present in the moving fluid reflect part of the acoustic wave sent by the emitter with a frequency shift depending on the particles’ velocity, which leads to the flow rate through the pipe. This type of flowmeter is particularly suited to flows with moderate to high particle concentrations.

PYTHEAS Technology designs and manufactures Doppler probes for the industry and biomedical applications.

A time-of-flight flowmeter has two reversible emitters/receivers, positioned on each side of the pipe to instrument. An acoustic wave is first sent from one transducer to the other, in one direction, then in the other. The difference of travel time between these two wave propagations gives the average speed of the fluid in the pipe, which leads to the flow rate. This type of flowmeter is particularly suited to flows with zero to low particle concentrations, since high particle concentrations can drastically decrease the acoustic propagation through the fluid.

PYTHEAS Technology designs time-of-flight for the industry for applications where a non-intrusive flow rate measurement is needed, and a low quantity of particles is present.