De-icing and ice detection are known problems in aeronautics, but also, more recently, in the field of wind power.

For aviation, different de-icing solutions exist, both on the ground and in flight, such as glycol fluid spraying, electrothermal systems (ETIPS), bleed air heat or pneumatic de-icing boots. These methods however present one or several issues among the following: their energy consumption, their cost, the workforce they require and their environmental impact.

Reducing aircrafts’ power consumption, including regional aircrafts, requires lighter de-icing technologies that consume less energy than at present.

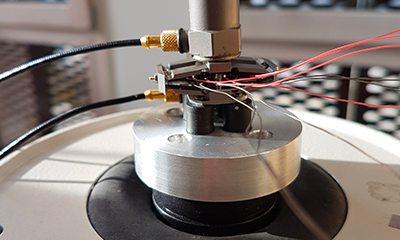

PYTHEAS Technology’s de-icing solution sets structures in vibration at one of their resonance modes, which breaks and removes ice for a low energy cost. This can be achieved thanks to piezoelectric actuators, for a reduced weight and size.

This embedded de-icing solution can also be used on wind turbines, which usually meet the same issues of onboard weight and energy consumption.

In addition to these advantages for de-icing, the technology offers the possibility of detecting the presence of ice and measuring its thickness using the same piezoelectric transducers.

Two methods exist using piezoelectric actuators for ice detection and measurement, namely pulse-echo and the measurement of the resonance frequency of the structure on which the transducer is fixed.

Piezoelectric technology, therefore, provides a solution combining de-icing, detection and measurement of frost in a single system, in a compact and lightweight manner and with low energy consumption.