Electrification of off-road vehicles: the magic bullet ?

The electrification of off-road vehicles makes it possible to reduce CO2, NOx and fine particle emissions from machines and increase their efficiency. More and more equipment manufacturers are turning to this alternative, by electrifying all or part of their machines, to reduce their environmental impact.

However, progress still needs to be made on a number of levels: from the battery volume and the environmental impact of its production, to the amount of energy needed to run the machine and the source of that energy.

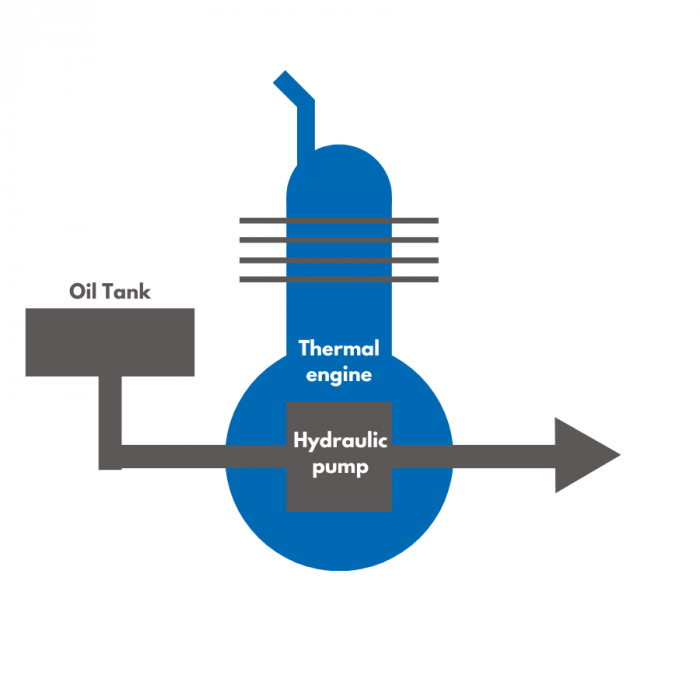

The electrification of off-road vehicles can help improve their efficiency. The efficiency represents the ratio between the energy provided by the fuel used and the one obtained, once transformed into mechanical energy. This represents another lever that can be used to reduce the environmental impact of off-road vehicles. By replacing the thermal engine with an electric motor and batteries, the efficiency of an off-road machine equipped with a hydraulic system would increase from 12% to 30%.

Before moving on to the electrification of off-road vehicles, we must therefore seek to improve the efficiency of their hydraulic systems. With a conventional hydraulic system, an electric off-road vehicle would have far too high power requirements to be relevant. The idea is therefore to optimize the hydraulic systems to make them more efficient and thus reduce the amount of energy needed to operate electric off-road machines (and reduce their battery requirements).

Different technical solutions aim to improve hydraulic systems. Today we will focus on an emerging solution: digital hydraulics.

Upgrading and improving hydraulic systems with digital hydraulics

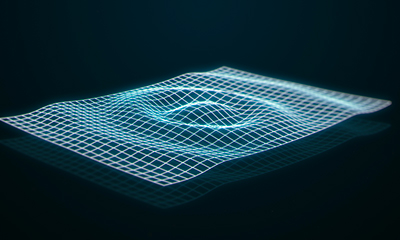

The digitalization of hydraulics consists in replacing a system of a given power by several systems of lower power operating in parallel and which will be activated on an all-or-nothing basis.

By forming a digital flow control unit (DFCU), the all-or-nothing (on/off) valves can vary the pressure and/or flow of a hydraulic circuit almost continuously, but with improved efficiency in comparison with current servovalves (Matti Linjama, Arto Lamaanen, Is it time for digital hydraulics?, 2003). This type of solution based on digital hydraulics certainly requires more valves, but the latter can be simpler and more reliable. In addition, these valves are digitally controlled, which makes them easier to control and more responsive.

The ultra-fast valve: an essential technological lock for the development of digital hydraulics

Compared to servovalves, on/off valves have pros and cons:

- Advantages:

- Less expensive

- Reliable

- Insensitive to contamination

- Leak-free

- Simple control electronics for easy connection to computers and PLCs

- Cavitation avoided thanks to separate control of inlet and outlet

- Drawbacks:

- Noise

- Pressure peaks

- Jerky movements

- Poor controllability

Digital hydraulics: an emerging technology in development

To democratize digital hydraulics, there are still challenges to overcome:

- Design more compact DFCUs thanks to smaller valves

- Reduce costs: digital hydraulics for water-based systems are cheap today, but digital hydraulics for oil-based systems remain even more expensive than traditional hydraulics.

- Reduce noise and pressure peaks

- Improve control with advanced algorithms and valves with reduced response times

- Provide valves suitable for a wider range of applications to democratize digital hydraulics (develop new models, tailor-made, etc.)

There is therefore still R&D work to be done to optimize digital hydraulics systems.

Electrification or digital hydraulics, where to start?

As we said previously, the final objective is to reduce the environmental impact of off-road vehicles and improve their performance.

The electrification of off-road vehicles is one of the solutions that could make this possible. However, this electrification cannot be viable without a significant improvement in hydraulic systems. Digital hydraulics therefore presents itself as a means of achieving this electrification objective.

The electrification of off-road vehicles through the use of digital hydraulics represents a large project, which can be divided into different stages. If electrification is the end goal, improving hydraulic systems with digital hydraulics can already be an end in itself. Digital hydraulics can make thermal engine vehicles more efficient, which is a first step towards reducing the environmental impact and increasing the efficiency of off-road vehicles.

What does PYTHEAS Technology do for digital hydraulics?

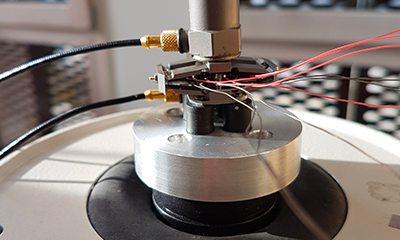

With the P4Hydro project, PYTHEAS Technology continues the development of its piezoelectric fast valves initially intended for its piezoelectric generator. Thanks to its very quick response time, this valve can meet the needs of developers of hydraulic transmissions and hydraulic components such as Poclain Hydraulics.

Poclain Hydraulics, an expert in hydrostatic and electro-hydraulic transmission, is studying the integration of PYTHEAS Technology valves into its future solutions for off-road machines.

To find out more about digital hydraulics and high-speed valves, do not hesitate to contact us!